Em geral, a costura deve ser ajustada de acordo com a seguinte sequência.

(1) Ajustar a base do pé de dobra da cabeça do costureiro de acordo com o tamanho do folheto

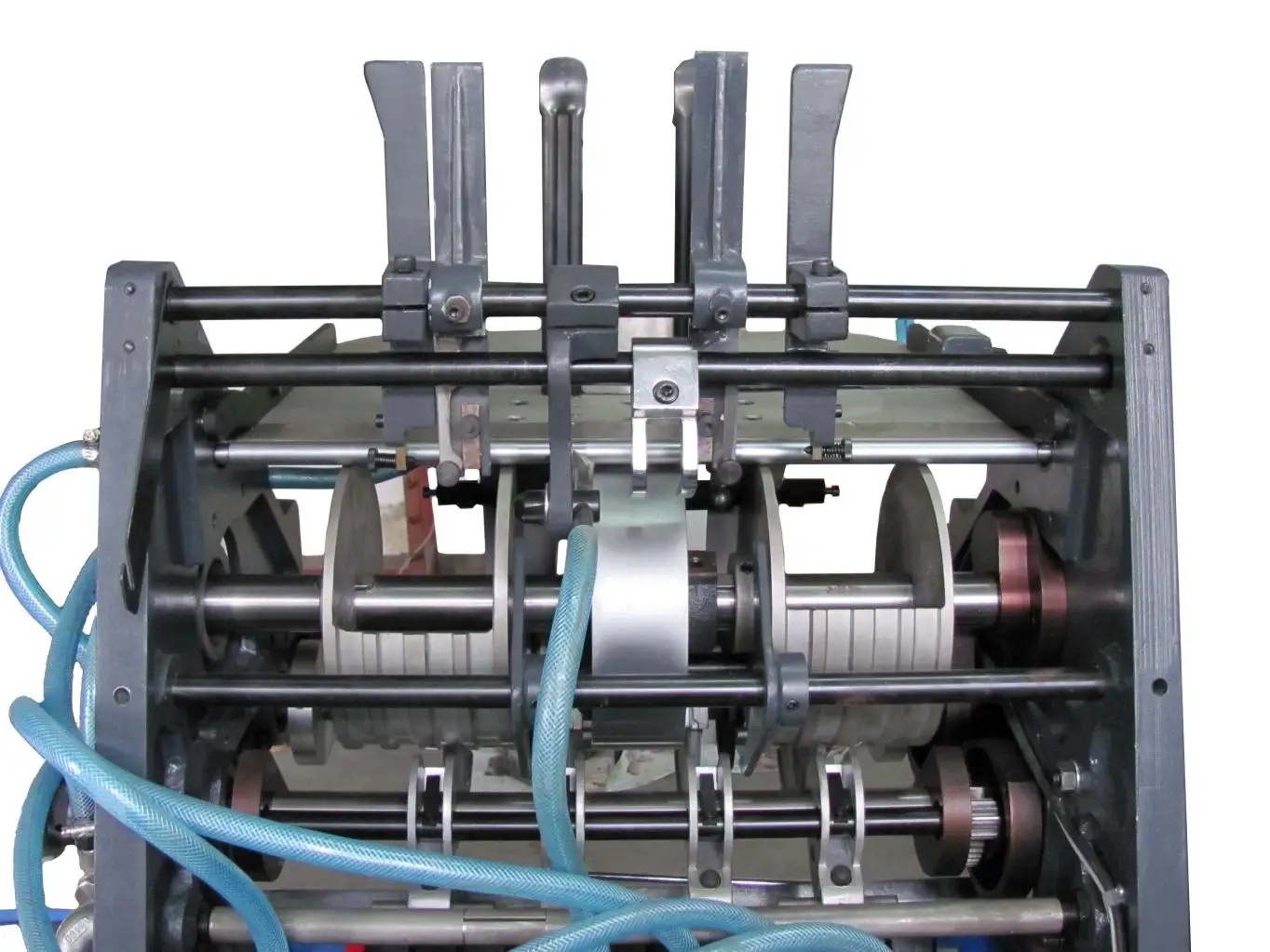

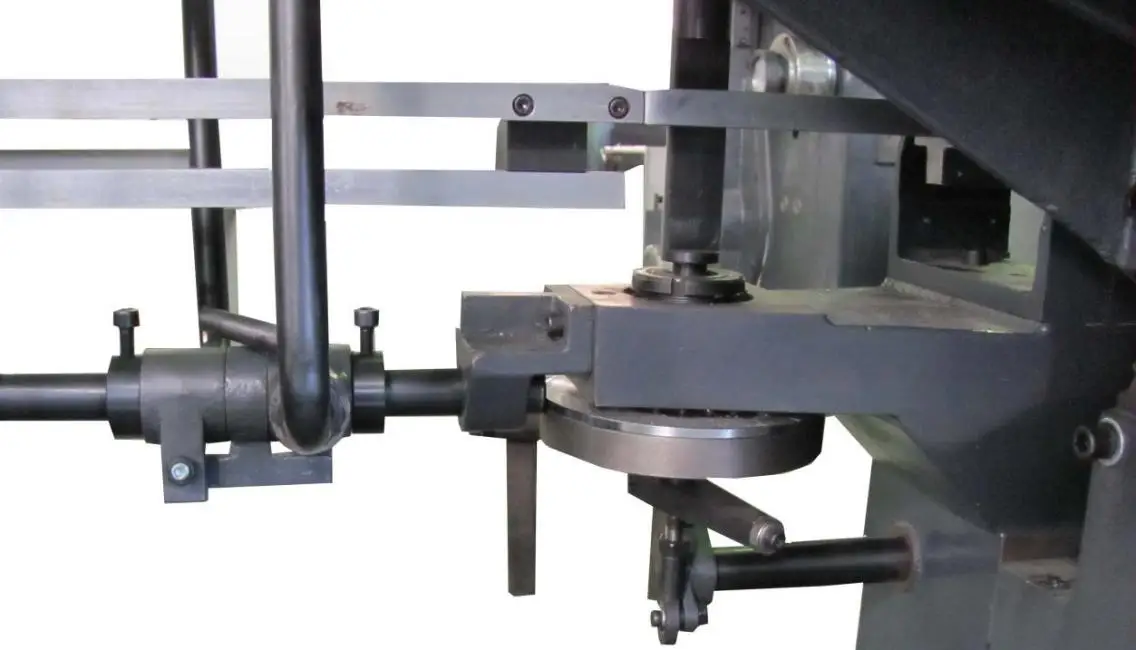

Em primeiro lugar, coloque a cabeça da costura sobre a placa de montagem da cabeça da costura simétrica à linha média (de acordo com as prescrições da costura da sela relativas à distância de empilhamento dos livros).E depois aperta o parafuso 27- e fixar o pé de curvatura 20 depois de o ter alinhado com a faca do centro da cabeça do costureiro, e instalar a placa de guia 28 ao mesmo tempo.

(2) Ajustar a cadeia de coleta de livros de acordo com o tamanho do folheto

No que respeita ao costureiro,a cadeia de recolha dos livros deve manter-se numa certa posição correcta, de modo a distribuir a costura da sela para as posições desejadas dos livros.Em caso de ajustamento,Em primeiro lugar, o livro para encadernação deve ser colocado na cadeia de recolha do livro, fazer a prensa de corte contra a placa transportadora de cauda,e operar a máquina manualmente para permitir que a cadeia de coleta de livros e a cabeça se movam para a frente ao mesmo tempoQuando a velocidade é a mesma, ou seja, eles estão em estado relativamente estático, parar a operação manual,soltar o parafuso 1 e girar o volante 2 para fazer o livro na cadeia de coleta de livros ser transmitido para o lugar certo para a ligação pela costura de sela, e, em seguida, fixar o parafuso 1, para que a posição correta do prego no livro pode ser garantida.

(3) Ajuste da posição do livro de bifurcação.

A posição correta para a bifurcação do livro pode fazer com que os livros jogados fora da prateleira de transmissão de livros do costureiro caia exatamente no meio dos dois suportes de escolha de livros do aparador de três facas.

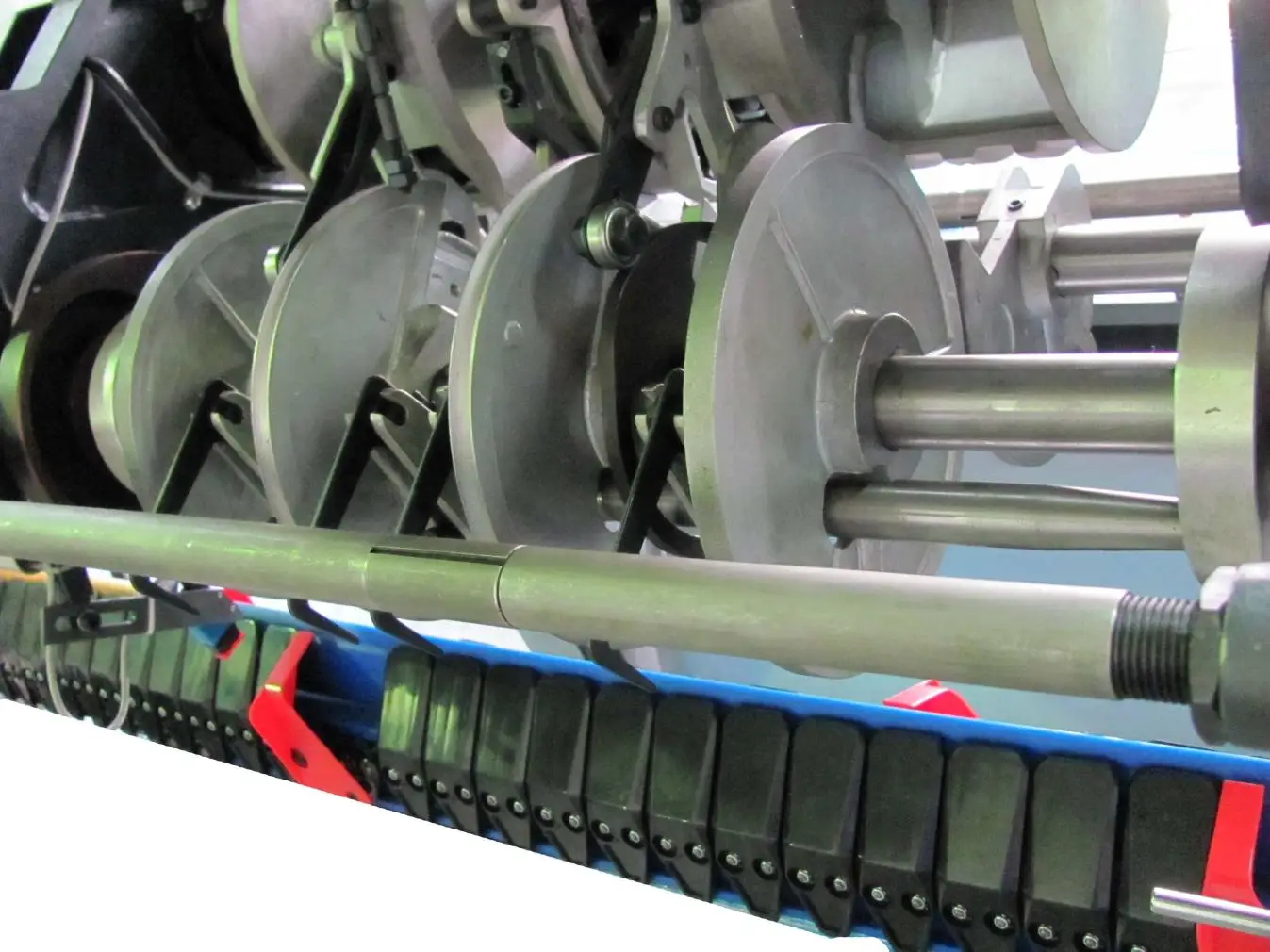

Determinação do tempo de bifurcação do livro:quando a camada 6 bifurca um livro para a posição mais elevada,a vara de ligação 2 puxa a cabeça para o limite esquerdo e retorna,mas deve manter uma distância de 60-65 mm com o porta-transmissãoEm seguida, instalar a engrenagem intermédia 1, de modo a garantir que o livro forcado pode cair em uma posição adequada.

Deve notar-se que a velocidade de bifurcação está estreitamente relacionada com a velocidade da própria máquina e que deve ser efectuada a correcção adequada com base na experiência de utilização.

(4) Ajuste do dispositivo de detecção

A detecção distribuída regula principalmente o interruptor fotoelétrico refletor e é instalada na posição relativa entre as películas refletoras na barra para caindo livros.O feixe de luz deve estar alinhado com a posição correta.

A detecção de página completa ajusta principalmente a altura de montagem dos dois interruptores fotoelétricos refletores em ambos os lados da cadeia de recolha de livros e o alinhamento do feixe de luz.De acordo com a posição da largura do livro de ligação na cadeia de colagem, os feixes de luz dos interruptores fotoeléctricos reflectantes devem ser colocados debaixo dos papéis dos livros a uma distância de 5 a 10 mm.Se forem encontrados papéis de livros distorcidos durante a transmissão na cadeia de recolha de livrosOs papéis dos livros protegerão o feixe de luz quando passarem pela posição de detecção, e os interruptores fotoeléctricos enviarão um sinal e descartarão o livro como um produto obsoleto.

Em caso de ajustamento da detecção geral da espessura, os livros normais de ligação devem ser colocados sob a roda excêntrica 1,operar a máquina manualmente e fazer a seta na roda excêntrica para baixoNeste momento, rodar o regulador 6, levantar o rolo inferior 3 do detector de livros para pressionar o livro no grau apropriado e, em seguida, ajustar ligeiramente a porca 13,para que possa ser deixado um espaço vertical adequado quando o bloco de contacto 4 se inserir no meio dos dois blocos 5.Em seguida, rodar a máquina um círculo, se os blocos podem inserir livremente, significa que o livro atende aos padrões de espessura normal.o costureiro será magneticamente suspenso numa posição de ligação.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!